-

ブルーノ・ナシメント高品質で手頃な価格の製品を提供してくれてありがとう

ブルーノ・ナシメント高品質で手頃な価格の製品を提供してくれてありがとう -

エフサン・サルマリ迅速な回答と専門的な態度により,私たちの協力はより円滑です!

エフサン・サルマリ迅速な回答と専門的な態度により,私たちの協力はより円滑です!

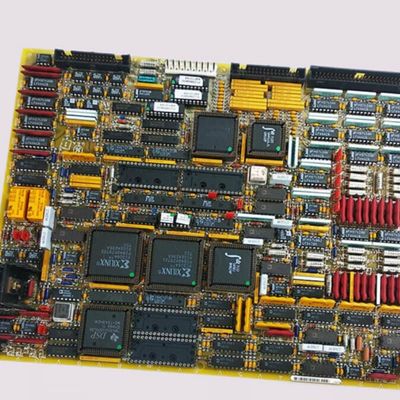

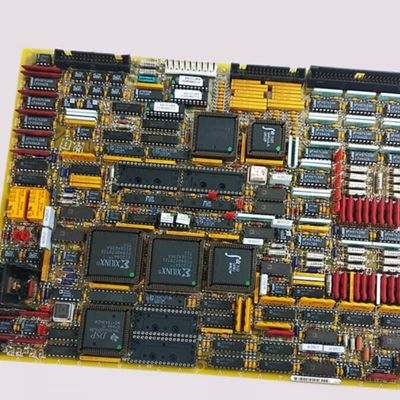

GE DS200TCQBG1BBA RST Mark Vシリーズ向け拡張アナログI/Oボード 柔軟なセンサー互換性と1年間の保証

| 名前 | GE DS200TCQBG1B DS200TCQBG1BBA RST拡張アナログI/Oボード | 製品ID | DS200TCQBG1BBA |

|---|---|---|---|

| シリーズ | マークv | 関数 | 離散出力パック |

| 製品ネットの深さ/長さ | 330mm | 製品ネットの高さ | 200mm |

| 製品ネット幅 | 100mm | 製品ネットウェイト | 2kg |

| 保証 | 1年 | ||

| ハイライト | 柔軟なセンサー互換性拡張アナログI/Oボード,1年保証 RST アナログ I/O ボード,2kg 体重マーク V I/Oボード |

||

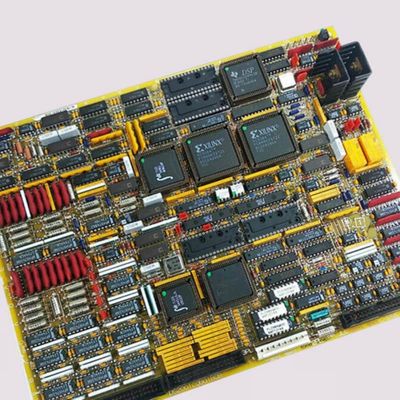

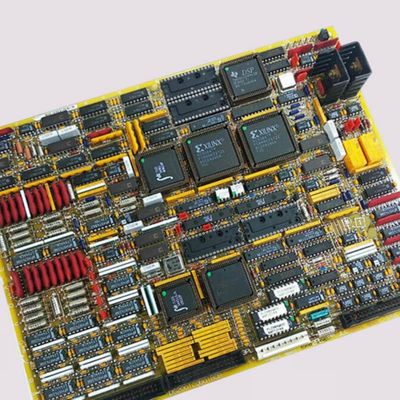

GEDS200TCQBG1BBAGE DS200TCQBG1BBA は、Mark V シリーズのガスタービン制御システム向けに調整された RST 拡張アナログ I/O ボードで、拡張された I/O 機能のためのオプションの多機能カードとして機能します。R、S、T コアにインストールされます。単純アプリケーションでは、R コアに 1 枚のカードのみが必要です。主に蒸気単純構成と、近接センサを必要とする一部の TMR システムで使用され、ハードウェアジャンパーとソフトウェア設定を介して近接トランスデューサと加速度計を切り替えることで、柔軟なセンサー統合をサポートします。その中核的な機能には、近接センサ入力、LVDT/LVDR 入力、2 つのレギュレータミリアンペア出力、LM 振動入力の管理が含まれており、Mark V システムの監視および制御範囲を拡張するための重要なコンポーネントとなっています。

主な特徴:

柔軟なセンサー互換性とコア固有の展開

このボードは適応性を持つように設計されています。近接トランスデューサと加速度計の両方に対応し、接続されたセンサーに基づいて正しいモードを設定するジャンパーを備えています。R/S/T コアに適合しますが、R コアカード 1 枚で単純構成を簡素化します。このボードと組み合わせた Mark V システムは、加速度計振動センサーを励起し、そのフィードバック信号をスケーリングできます。これにより、タービンの健全性にとって重要な振動監視機能が拡張されます。

正確な EPROM の取り付けと機能の一貫性

EPROM を取り付けるには、モジュールをソケットに合わせ、しっかりと押して、しっかりと物理的に接続する必要があります。重要なベストプラクティスは、古い EPROM のファームウェアとプログラミングを保持し、交換用ボードがオリジナルと同一に動作するようにすることです。これにより、タービン制御ロジックを中断する可能性のある不一致を回避できます。この一貫性は、交換後のシステムの信頼性を維持するための鍵となります。

タービン制御のための拡張 I/O 機能

センサー管理に加えて、専門的な I/O 機能を提供します。2 つのレギュレータミリアンペア出力により、下流デバイスを正確に制御し、LVDT/LVDR 入力により、線形位置を監視し、近接センサ/LM 振動入力により、回転/構造の健全性を追跡できます。これらの機能により、Mark V システムが重要なタービンデータを収集および処理する能力が拡張され、よりきめ細かい制御と予測メンテナンスがサポートされます。

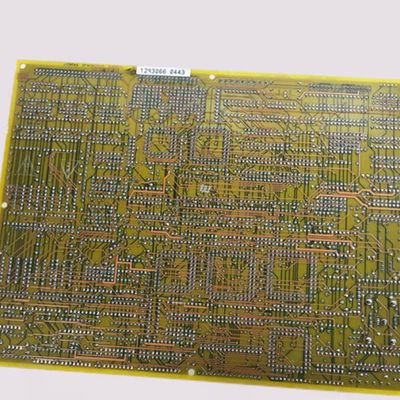

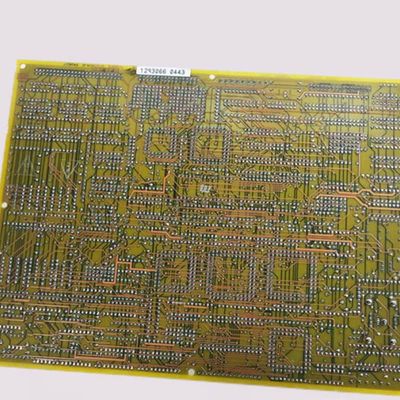

定義された物理的寸法と軽量設計

寸法は 13.50 x 9.00 x 2.00 で、重量は 1.80 ポンドで、コンパクトで軽量なフォームファクタを備えています。この設計は、Mark V コアのスペース制約にシームレスに適合し、他のコンポーネントとの干渉を回避し、取り付けと交換中の取り扱いを容易にします。